Products

Mud Pumps

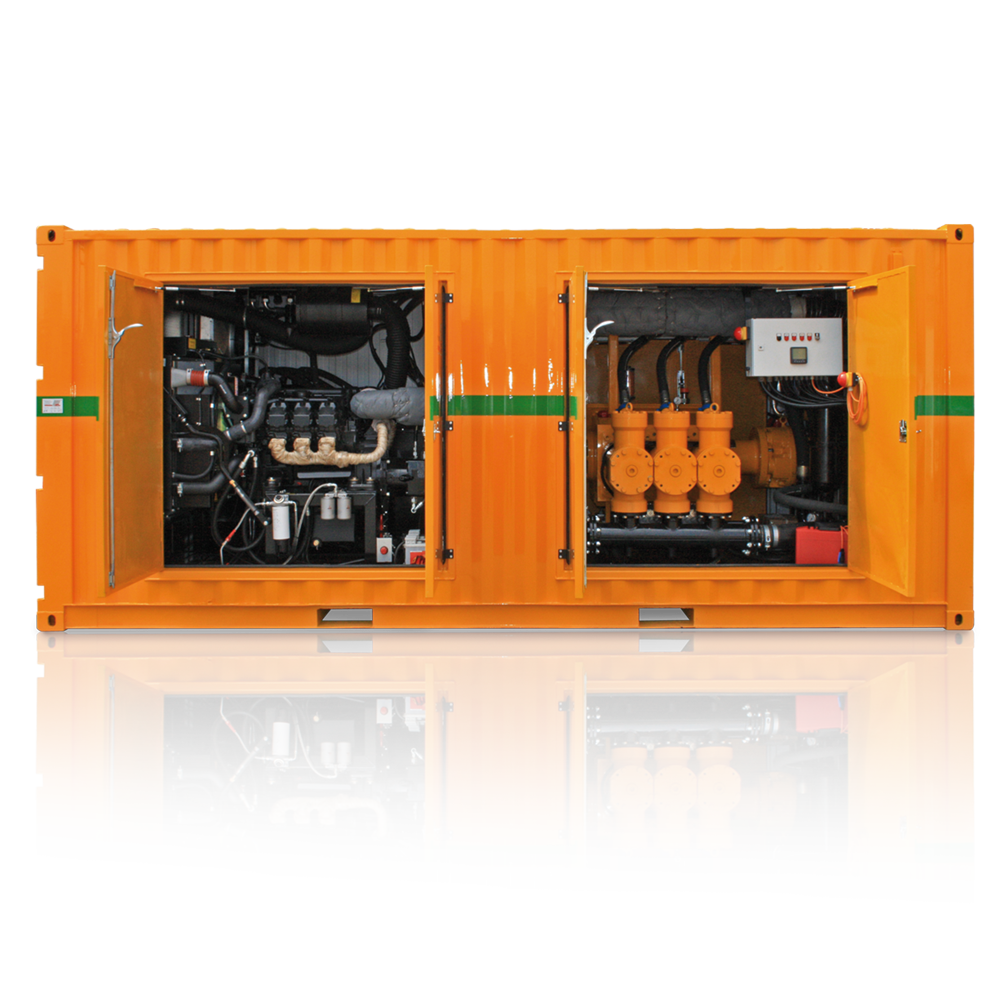

Our high pressure mud pumps are available from 800 LPM to 3500 LPM with pressures from 95 to 120 bar. All pumps are installed in a 20 ft container. For easy service the system is built on a skid that can be easy pulled out of the container. Optional they also can be installed just on a flat rack.

834 l/min - 1.307 l/min

Max. Flow Pressure:

124 bar - 135 bar

Drive:

150 rpm - 235 rpm

Drive Power:

130 kW - 240 kW

The X-series mud pump type PD X-1.000 HD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 235 rotations per minute operational wear is reduced to a minimum.

The use of most modern hydraulic components enable continuous control of the shaft speed and the thus generated linear speed of pistons or rather the flow rate of the drilling fluid by the speed of the hydraulic motor. The pump has a compact design and is installed into a silenced 20 ft. container. The integrated skid system allows to pull the pump out of the container fast and easily for service and maintenance. The container is designed as such to enable fast and easy transport via a twist-lock system.

1.613 l/min - 2.445 l/min

Max. Flow Pressure:

110 bar

Drive:

155 rpm - 235 rpm

Drive Power:

256 kW - 380 kW

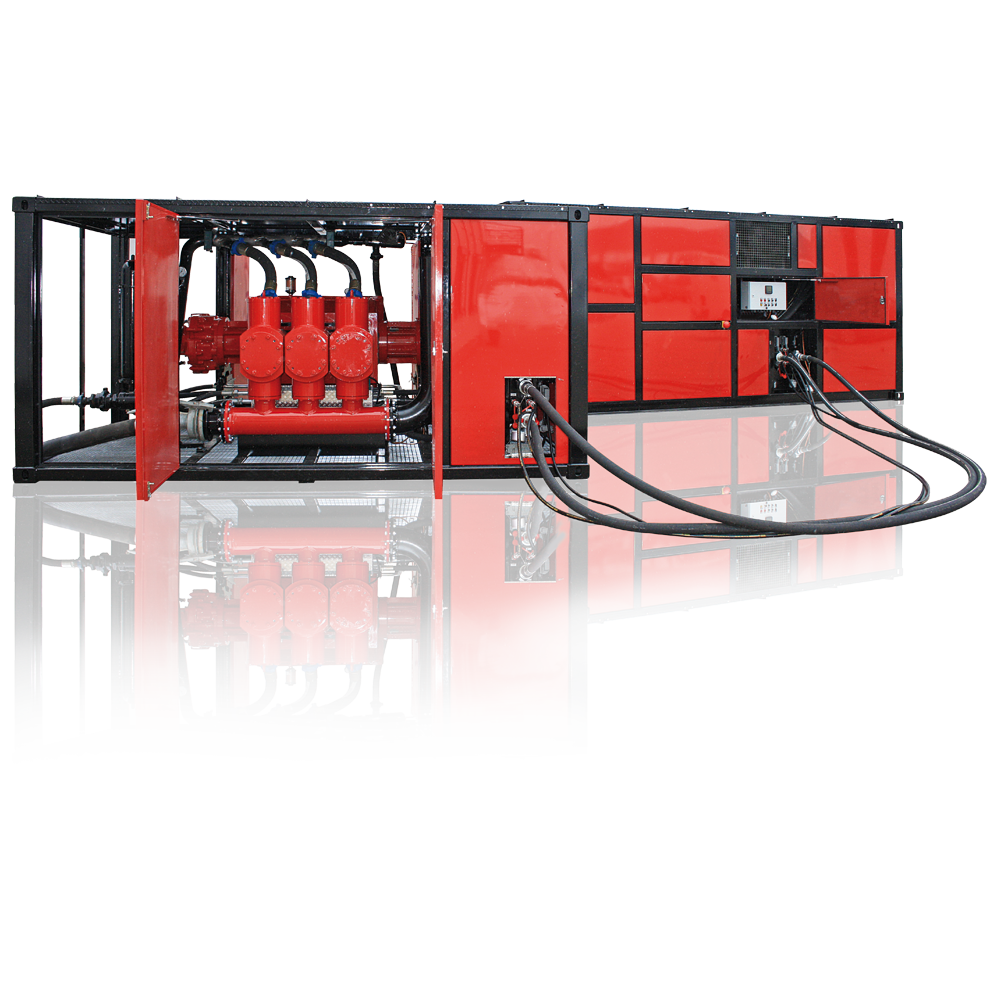

The X-series mud pump type PD X-2.000 HD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 235 rotations per minute operational wear is reduced to a minimum.

The use of most modern hydraulic components enable continuous control of the shaft speed and the thus generated linear speed of pistons or rather the flow rate of the drilling fluid by the speed of the hydraulic motor. The pump has a compact design and is installed into a silenced 20 ft. container. The integrated skid system allows to pull the pump out of the container fast and easily for service and maintenance. The container is designed as such to enable fast and easy transport via a twist-lock system.

2.737 l/min - 3.497 l/min

Max. Flow Pressure:

113 bar

Drive:

180 rpm - 230 rpm

Drive Power:

470 kW - 570 kW

The X-series mud pump type PD X-3.000 HD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 230 rotations per minute operational wear is reduced to a minimum.

The use of most modern hydraulic components enable continuous control of the shaft speed and the thus generated linear speed of pistons or rather the flow rate of the drilling fluid by the speed of the hydraulic motor. The pump has a compact design and is installed into a silenced 20 ft. container. The integrated skid system allows to pull the pump out of the container fast and easily for service and maintenance. The container is designed as such to enable fast and easy transport via a twist-lock system.

3.190 l/min

Max. Flow Pressure:

60 bar

Drive:

230 rpm

Drive Power:

470 kW

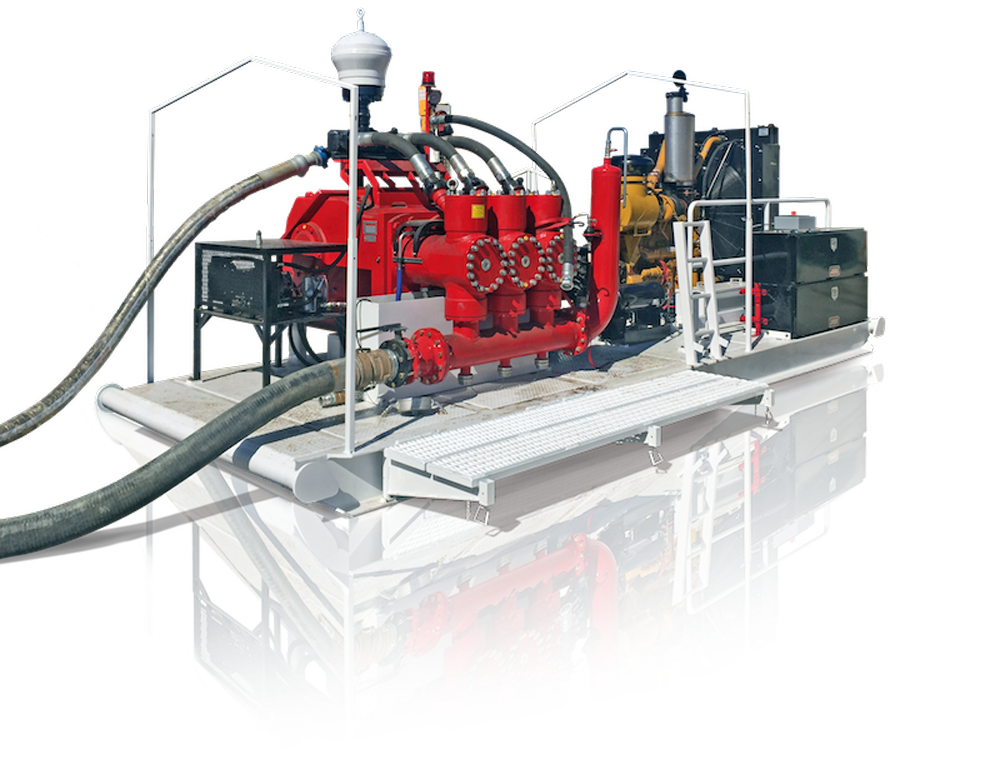

The X-series mud pump type PD X-3.004 SG HDD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 230 rotations per minute operational wear of rubbers and liners are reduced to a minimum.

The pump is driven by a 470 kW CAT engine. This type of mud pump is exclusively manufactured in our Wenden plant, i.e. „made in Germany“. Its electronic gearshift in combination with eccentric wheels used instead of a crankshaft make it a high- power but low- maintenance product. All valves and plungers also comply with API standards.